Q: How does a project capacitive touch panel work?

A: Most P-Cap touch panels are made of three components: the sensor glass, the cover glass and the controller. The sensor glass is constructed of rows and columns of a transparent conductive coating called Indium Tin Oxide (ITO). Each row and column is an electrode and is used for sensing the location of the touch. All the electrodes are routed back to a connection point where the signal of a touch is sent via a flat printed circuit to the controller. Over the top of the grid of ITO, a cover glass is laminated. The cover glass serves as a dielectric between your finger and the electrodes and also serves as a protective barrier for the electrodes. When somebody touches the cover glass a small charge is pulled from the rows and columns on the sensor glass and this signal is routed back to the controller. Using advanced algorithms, the controller can determine the location of the touch and send the coordinates of the touch to the computer.

Q: What is multi-touch?

A: Multi-touch is the capability to unambiguously sense two or more touches at the same time.

Q: How many touch points will the sensor recognize?

A: Depending on the system, most projected capacitive sensors will recognize between 10 and 80 discrete touch points.

Q: What are the benefits of multi- touch?

A: P-Cap touch panels with multi-touch capability take some of the control of your keyboard and mouse and put it on your screen. Defined gestures allow the user to perform functions such as manipulate photos, scroll through documents and pan across maps with intuitive motions on the screen instead of having to go back to a mouse or type various commands on a keyboard.

Q: What is the difference between self-capacitance and mutual capacitance?

A: The major differences between the two are the method by which they scan the touch sensor and the method by which they sense a touch. Most of MicroTouch’s products use mutual capacitance.

Scanning: P-Cap sensors are constructed of conductive rows and columns that make up a grid on the touch sensor. With self-capacitance, each of these rows and columns are scanned one at a time. If a sensor is made up of 10 rows and 15 columns of electrodes, to scan the entire sensor you would need to scan 10+15 or 25 electrodes. With mutual capacitance you need to scan the intersections of the electrodes, where the rows and columns overlap. The 10 rows and 15 columns intersect at 10×15 or 150 intersections, so to scan the entire sensor you would need to scan at every one of those 150 intersections.

Sensing: In self-capacitance technology, a touch changes the capacitance of an electrode with respect to ground. With mutual capacitance, a touch takes some of the charge from the field that is created at the intersection of electrodes.

Q: What is “Ghosting”?

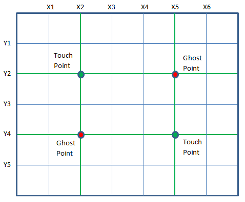

A: Ghosting is one of the major problems that occur with self-capacitance touch screens; the problem does not exist with mutual capacitance touch screens. When you are sensing by only scanning the rows and columns individually and not looking at the intersections, two touch points that are diagonal from one another will have a pair of “ghost” touch points (see diagram). When your actual touch points are X2,Y2 and X5,Y4, the controller has no way of determining if you are touching the points you actually want or if you are touching the mirrored points of X2,Y4 and X5,Y2.

Q: In what type of environments does P-Cap touch panels work best?

A: P-Cap technology works best in environments where you can have direct finger-to- touch panel interaction. The glass/glass construction makes them immune to most chemicals and allows them to operate in extreme temperatures. The ability to make P-Cap sensors into a flush mount design that can be completely sealed makes them ideal for any application where cleanliness is critical. Their ability to be used with thin rubber gloves allows them to be used for most medical applications.

Q: How durable are P-Cap touch panels?

A: The construction of a P-Cap panel makes it one of the most durable touch screens available. In the P-Cap construction, all the sensitive electronics are buried within the stack of the lamination. The active electronics are beneath the coverglass, where, unlike other touch solutions, they are not susceptible to wear.

In order to cause damage that would affect the performance of the screen you would need to completely break the touch panel or be able to scratch through the thickness of the cover glass.

Q: Does a P-Cap sensor need to be calibrated?

A: P-Cap touch panels are generally automatically calibrated at startup. There is no need for manual calibration by the operator.

Q: Are P-Cap sensors easy to integrate?

A: Yes and no. Mechanically, they are very easy to integrate. The flush mount design of our Fusion product allows for easy integration into your industrial design. Electrically, they are a little more difficult. As with any type of capacitive technology, there is an interaction between the touch panel and its surrounding environment that needs to be taken into consideration when initially setting up the touch panel. The experts at Touch Revolution will work with you every step of the way to set up the firmware so that the touch panel has optimum performance for your application.

Q: What is the advantage of an integrated touch display as compared to having the customer integrate their own LCD, touch panel, and controller?

A: The proper integration of the touch sensor to the LCD is crucial for superior performance. The touch sensor must be “tuned” to each LCD model to compensate for any noise that the LCD may be inducing onto the touch sensor. This is a very difficult process and should be done in a controlled environment. The touch sensor also needs to be designed in conjunction with the controller. An off-the-shelf controller will not necessarily work with any touch sensor.

Q: What LCDs are we using in MicroTouch’s touch displays?

A: MicroTouch is using LCDs from leading LCD suppliers worldwide. Every MicroTouch touch display specification contains the LCD specification within the document.

Q: What types of customers/applications are interested in P-Cap

A: Since P-Cap can be a more expensive option than resistive, the customer must be willing to pay more for P-Cap’s value proposition. P-Cap gives the customer the ability to have a flat front surface without an bezel, have multi-touch capabilities, offer high reliability, and have an excellent touch experience.

Q: What is the value proposition of P-Cap over the life of a customer’s product that makes the technology cost-effective over lower cost touch technologies?

A: P-Cap is a rugged and reliable touch technology which corresponds to long life and very few field failures. Customers can save money over the life of the product.