How Projected Capacitive Touch Technology Works

Capacitive sensing in touch screens has been around since the 1970’s, but with the recent explosion in popularity of smartphones and tablets, projected capacitive sensors have come to the forefront of touch screen technology.

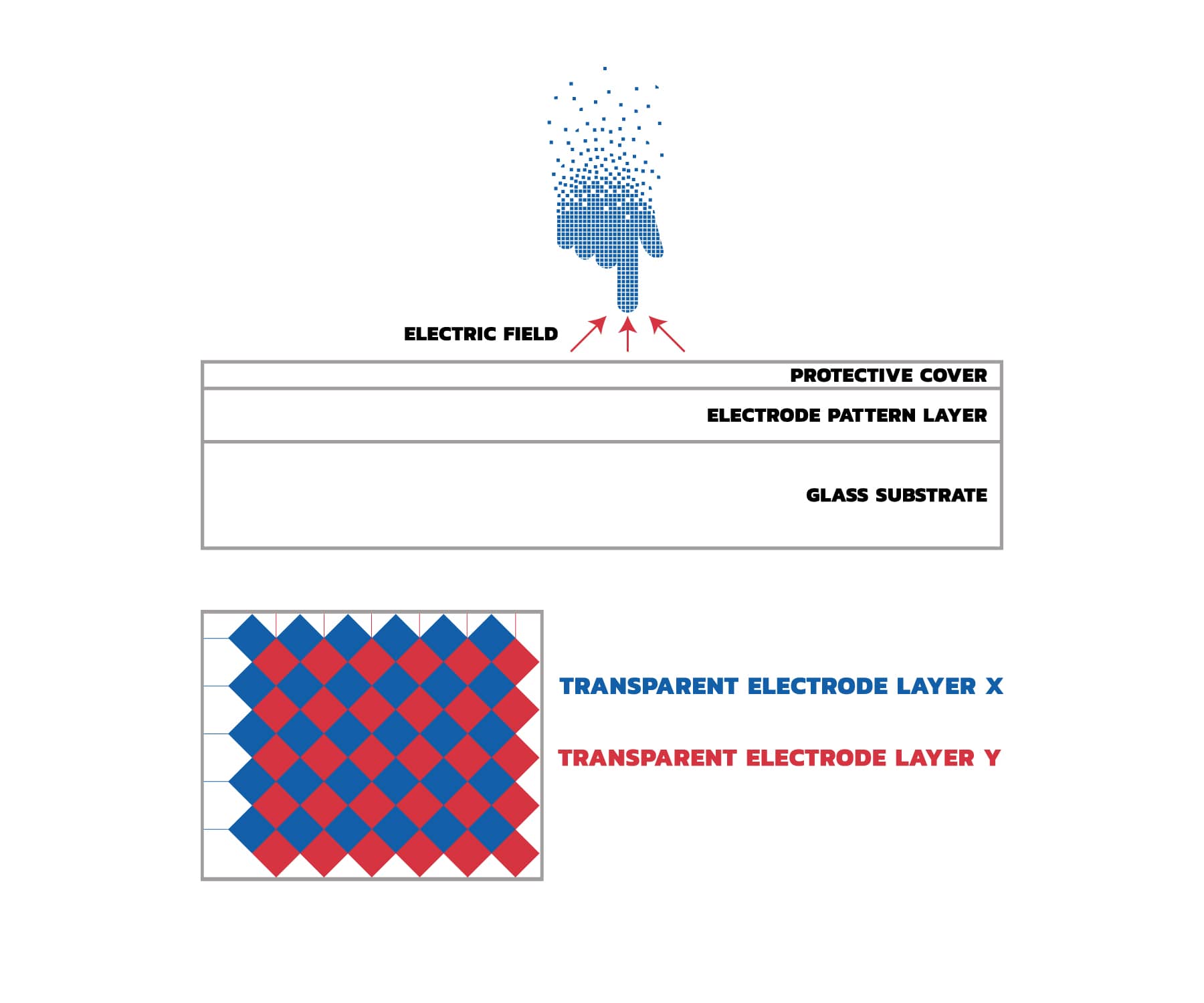

Most commonly, projected capacitive sensors are made up of three major components; the sensor glass, the cover glass, and a flexible printed circuit (FPC) with controller. The sensor glass is made up of a series of electrodes that are configured into rows and columns. These electrodes are made of a transparent conductive coating called indium tin oxide (ITO). Each electrode is routed back with a metal trace to a connection point where the FPC can be be bonded. The FPC generally contains the controller for the touch sensor.

The cover glass is optically bonded on top of the sensor glass, burying the electrodes within the stack of the lamination. The cover glass serves as a dielectric between your touch and the electrodes of the sensor glass. It also doubles as a barrier layer, protecting the sensitive electrodes from the environment and any potential damage.

The controller continually scans and monitors the capacitance of the electrodes. When your finger touches the surface of the cover glass it pulls a small charge from the electrodes and using complex algorithms the controller can determine the exact location of your touch.

Projected capacitive touch technology has many benefits including multi-touch capability, extreme durability and superior optics.